|

|

|

|

CPT Steve

|

Date: 9-10-2009

|

Number of Hours: 1.60

|

Manual Reference: 02A-2

|

Brief Description: ROLLED EDGE ON RUDDER SKIN

|

|

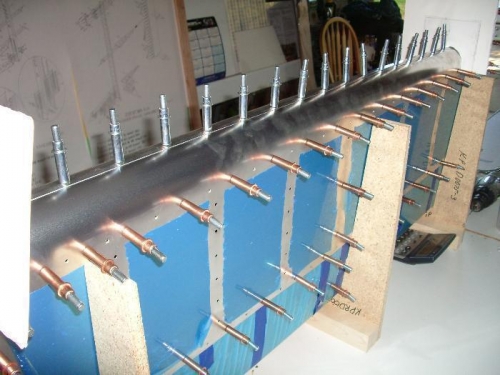

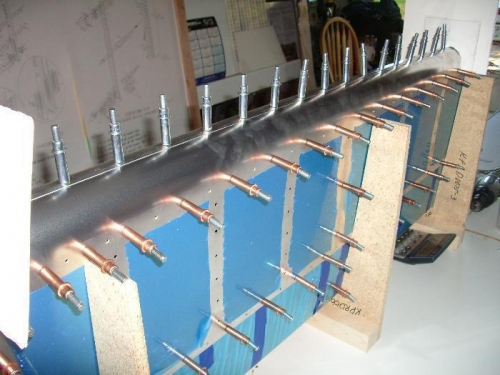

(1) I purchased a piece of aluminum tubing to accomplish the bend on the leading edges of the rudder skins, and had the tube cut to the length required.

(2) I clamped the cut piece of aluminum tubing to the edge of my work bench, and using a fine point sharpie and a small block of grooved wood, I marked a straight line down the side of the tube.

(3) After unclamping, I laid out the side of the skin that I had previously rolled the edge on, and set it along the line on the tube. Careful to keep my alignment, I taped it to the tube, and actually used a couple of clamps to keep it from moving until I had a few of the holes drilled and clecoed.

(4) I placed some sand bags on the skin to hold it firm, and rolled the edge untilit was in the approximate shape. Repeated this procedure on the other side, and reinstalled the skin in the jig.

(5) I cut out the templates from the pictures in the manual and mounted them on a fiber board.

(6) I clecoed the skins and the leading edge and checked with the templates to verify the shape of the leading edge. Everything looked good, and I was finally past that skill. I had been working that one out in my mind for quite a while, and was relieved when it turned out like it did.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|